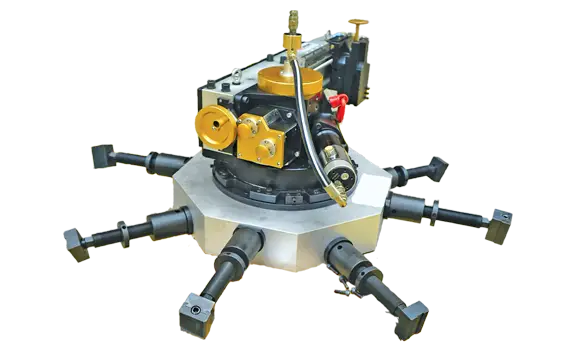

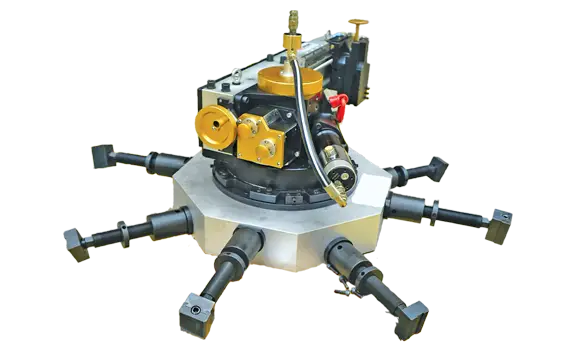

Flange Facing Machine

Metal Stitch recognize that flange integrity is achieved through precision machining. Our TTFF series flange facing machine delivers ASME/API code-compliant surface finishes with strict profile and tolerance control; restoring worn or distorted flanges on-site with repeatable accuracy, ensuring leak-free performance without costly disassembly. ⦁ Unlike conventional grinding or lapping, our robust OD/ID mountable design enables quick setup in any orientation horizontal, vertical, or inverted minimizing downtime and operator fatigue. ⦁ Securely clamps onto flange bore or OD with fine-adjustment jacking screws, delivering rigid, vibration-free machining even on warped, corroded, or distorted flanges. ⦁ Engineered to machine smooth, raised face, RTJ grooves, lens rings, and tongue-and-groove profiles with a 360° swivel tool post, delivering full profile versatility. ⦁ Automatic and manual feed systems provide controlled depth of cut (0.05–0.3 mm), ensuring both roughing and finishing operations can be achieved with one setup. ⦁ Compact, modular design allows interchangeable facing arms and tool holders, supporting multiple machining tasks without the need for separate equipment. ⦁ Available with manual, pneumatic, hydraulic, or CNC drive options, ensuring adaptability across offshore platforms, refineries, petrochemical plants, and power stations. ⦁ Performs cold, spark-free machining, eliminating heat-affected zones and ignition risks—making it inherently safe for use in hazardous, gas-sensitive, or explosive environments. ⦁ Equipped with a filter-regulator-lubricator (FRL) system on pneumatic models, ensuring consistent motor performance, longer service life, and safe operation. ⦁ Suitable for on-site flange facing up to 118" OD.

Flange Facing Machine

Metal Stitch recognize that flange integrity is achieved through precision machining. Our TTFF series flange facing machine delivers ASME/API code-compliant surface finishes with strict profile and tolerance control; restoring worn or distorted flanges on-site with repeatable accuracy, ensuring leak-free performance without costly disassembly.

- Unlike conventional grinding or lapping, our robust OD/ID mountable design enables quick setup in any orientation horizontal, vertical, or inverted minimizing downtime and operator fatigue.

- Securely clamps onto flange bore or OD with fine-adjustment jacking screws, delivering rigid, vibration-free machining even on warped, corroded, or distorted flanges.

- Engineered to machine smooth, raised face, RTJ grooves, lens rings, and tongue-and-groove profiles with a 360° swivel tool post, delivering full profile versatility.

- Automatic and manual feed systems provide controlled depth of cut (0.05–0.3 mm), ensuring both roughing and finishing operations can be achieved with one setup.

- Compact, modular design allows interchangeable facing arms and tool holders, supporting multiple machining tasks without the need for separate equipment.

- Available with manual, pneumatic, hydraulic, or CNC drive options, ensuring adaptability across offshore platforms, refineries, petrochemical plants, and power stations.

- Performs cold, spark-free machining, eliminating heat-affected zones and ignition risks—making it inherently safe for use in hazardous, gas-sensitive, or explosive environments.

- Equipped with a filter-regulator-lubricator (FRL) system on pneumatic models, ensuring consistent motor performance, longer service life, and safe operation.

- Suitable for on-site flange facing up to 118" OD.

Ready to Work with Us?

Contact our team today to discover how Metal Stitch can deliver exceptional industrial solutions for your needs.